Answer to Question 1

Step 1: Define the Logistics/Supply Chain Network Design Process

Of initial importance is the formation of a logistics/supply chain network transformation team to be responsible for all elements of the network design process. This team will first need to become aware of overall corporate and business strategies and the underlying business needs of the firm and the supply chains in which it is a participant.

Also in this step, it is important to establish the parameters and objectives of the network design or redesign process itself. Issues pertaining to the availability of needed resources in the areas of funding, people, and systems must be understood at an early stage in the process. An additional topic to be addressed early on is the potential involvement of third-party suppliers of logistics services as a means of achieving the firm's logistics objectives.

Step 2: Perform a Logistics/Supply Chain Audit

The logistics/supply chain audit provides members of the transformation team with a comprehensive perspective on the firm's logistics process. In addition, it helps to gather essential types of information that will be useful throughout future steps in the redesign process such as: customer requirements and key environmental factors; key logistics goals and objectives; profile of the current logistics/supply chain network; understanding of key logistic/supply chain activities and processes; benchmark, or target, values for logistics/supply chain costs and key performance measurements; identification of gaps between current and desired logistics/supply chain performance, and key objectives for logistics/supply chain network design.

Step 3: Examine the Logistics/Supply Chain Network Alternatives

The next step is to examine the available alternatives for the logistics/supply chain network. This involves applying suitable quantitative models to the current logistics system as well as to the alternative systems and approaches under consideration. The use of these models provides considerable insight into the functioning and cost/service effectiveness of the various possible networks.

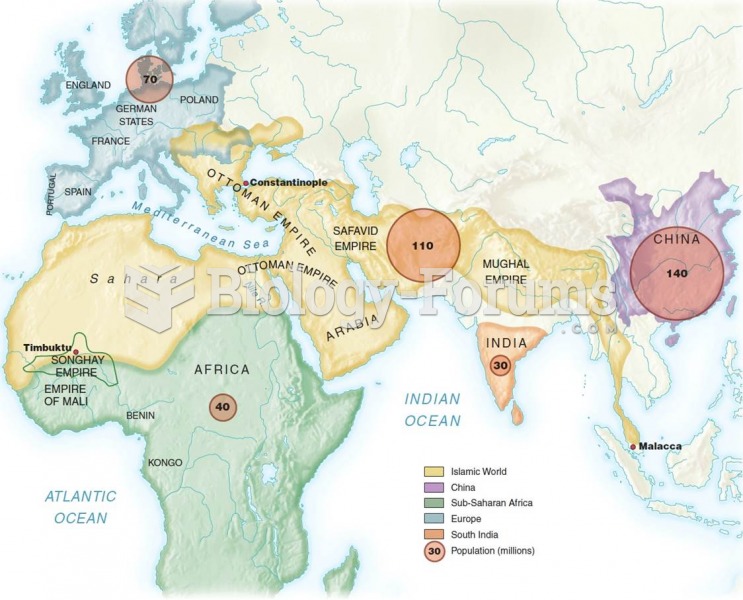

Also, at this point in the network design process, it is critical to understand the geographical parameters of the logistics/supply chain under study.

Step 4: Conduct a Facility Location Analysis

Once a general configuration of the desired logistics/supply chain network has been recommended, the next task is to carefully analyze the attributes of specific regions and locales that are candidates for sites of logistics facilities, distribution centers, cross-docking operations, etc. These analyses will have both quantitative and qualitative aspects.

The effort in this step will be facilitated by the formation of a location selection team, which will collect information on specific attributes as well as to examine potential sites in terms of local factors such as topography, geology, and facility design.

Step 5: Make Decisions Regarding Network and Facility Location

The network and specific sites for logistics facilities recommended in Steps 3 and 4 should be evaluated for consistency with the design criteria that were identified in Step 1 . This step should confirm the types of change that are needed to the firm's logistics network and should do so in the context of overall supply chain positioning.

Step 6: Develop an Implementation Plan

Once the overall direction has been established, the development of an effective implementation plan, or blueprint for change, is critical. This plan should serve as a useful road map for moving from the current logistics/supply chain network to the desired new one.

Answer to Question 2

a