|

|

|

Did you know?

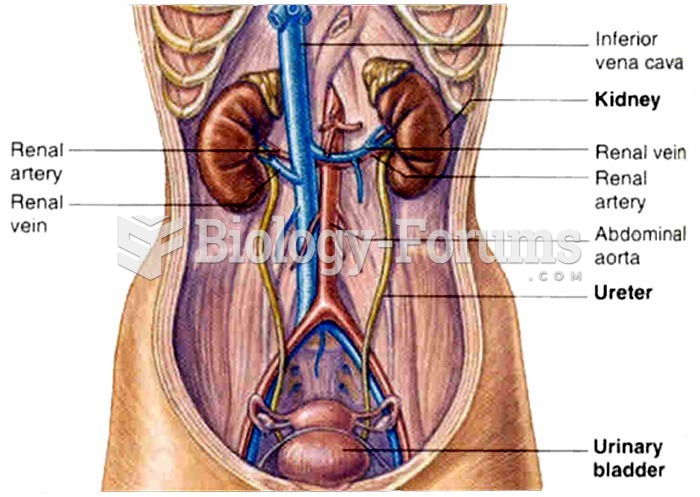

In most climates, 8 to 10 glasses of water per day is recommended for adults. The best indicator for adequate fluid intake is frequent, clear urination.

Did you know?

Intradermal injections are somewhat difficult to correctly administer because the skin layers are so thin that it is easy to accidentally punch through to the deeper subcutaneous layer.

Did you know?

About 100 new prescription or over-the-counter drugs come into the U.S. market every year.

Did you know?

Anti-aging claims should not ever be believed. There is no supplement, medication, or any other substance that has been proven to slow or stop the aging process.

Did you know?

Excessive alcohol use costs the country approximately $235 billion every year.