|

|

|

Anti-aging claims should not ever be believed. There is no supplement, medication, or any other substance that has been proven to slow or stop the aging process.

The strongest synthetic topical retinoid drug available, tazarotene, is used to treat sun-damaged skin, acne, and psoriasis.

It is believed that the Incas used anesthesia. Evidence supports the theory that shamans chewed cocoa leaves and drilled holes into the heads of patients (letting evil spirits escape), spitting into the wounds they made. The mixture of cocaine, saliva, and resin numbed the site enough to allow hours of drilling.

According to the Migraine Research Foundation, migraines are the third most prevalent illness in the world. Women are most affected (18%), followed by children of both sexes (10%), and men (6%).

Your chance of developing a kidney stone is 1 in 10. In recent years, approximately 3.7 million people in the United States were diagnosed with a kidney disease.

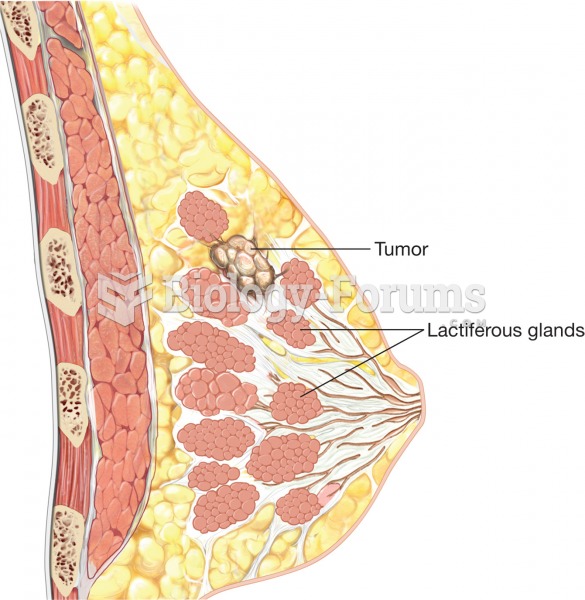

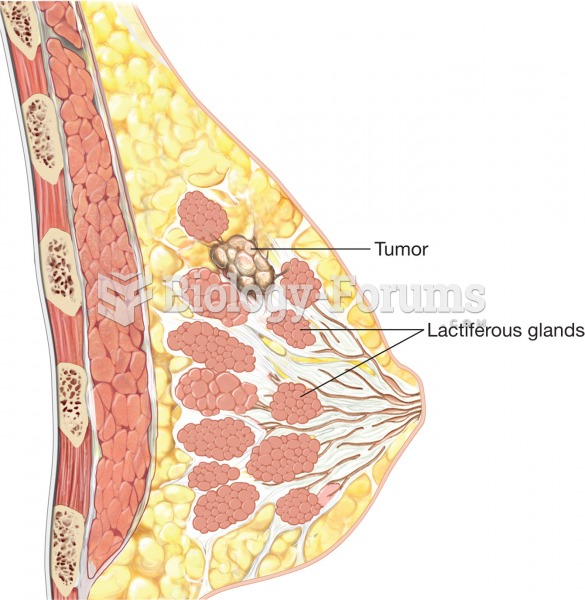

Breast cancer. Notice the tumor growing within a lactiferous gland, which occurs in infiltrating duc

Breast cancer. Notice the tumor growing within a lactiferous gland, which occurs in infiltrating duc

Breast cancer. Notice the tumor growing within a lactiferous gland, which occurs in infiltrating duc

Breast cancer. Notice the tumor growing within a lactiferous gland, which occurs in infiltrating duc